Large Part Manufacturing • Value-Added Services • Fully Functional Assemblies

Recent Projects

PROJECT TITLE:

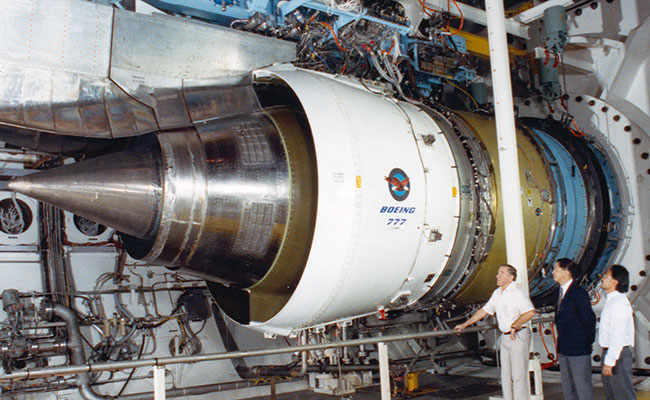

GE 9X Boat Tail project

PROJECT DESCRIPTION:

Procure the necessary materials for machining, source formed sheet metal, mechanically assemble, and inspection of the entire system.

CAPABILITIES APPLIED/PROCESSES

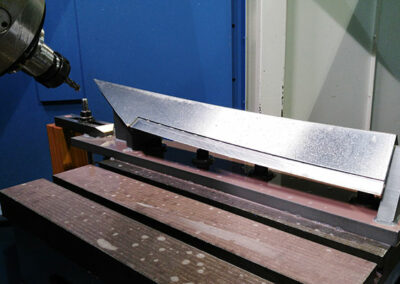

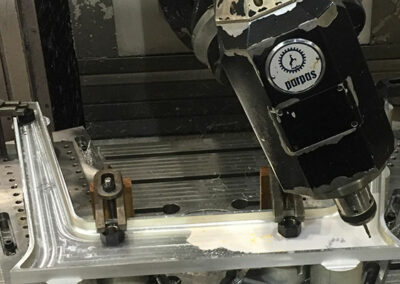

Primary: 5 Axis machining

Secondary: Forming complex shapes from Stainless steel and inconel.

EQUIPMENT USED TO MANUFACTURE PART

- Ibarmia Mill-Turn 5 Axis machining center

OVERALL PART DIMENSIONS

- Length: 205”

- Height: 50”

- Width: 42”

- Weight: 1680 lbs

TIGHTEST TOLERANCES

- As low as .0005

- .005 Profiles

MATERIAL USED

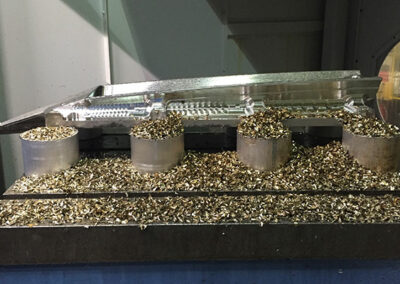

- Aluminum, Stainless Steel, Inconel, bronze, MP159

MATERIAL FINISH

- 32 Finish

INDUSTRY FOR USE

- Aerospace

IN PROCESS TESTING/INSPECTION PERFORMED

- Conventional inspection

- Laser Tracker

- Faro Arm

- Laser Scan

VOLUME

- 7 total Units

DELIVERY/TURNAROUND TIME

- 6 months’ lead-time

- 1 unit every 7 weeks thereafter

DELIVERY LOCATION

- US

- France

- Japan

STANDARDS MET

- ISO 9001

SPECIAL FEATURES

- Profile tolerance of assembly +/- .032

NOTABLE

Complex assembly that showcases machining, assembly and inspection capabilities

The client chose us based on our work correcting another supplier’s similar hardware.

Difficulties Overcome: Tolerancing of the formed sheet metal parts. A lot of trial and error to get things within tolerance.

Positive Client Feedback: Profiles that meet the aircraft builder’s specifications for actual flight hardware.

Special Feature of this Product: Complex profiles machined into multiple alloys of material.

Finished Product: All disciplines within Magna were utilized in the manufacture of this assembly.

CONTACT US

Our experts are ready to discuss our capabilities and your needs.

Project Gallery

Click on a photo to view a larger image.

Completed Project Photography

Magna Machine Company

11180 Southland Road

Cincinnati, OH 45240

Ph: 513.851.6900

© Magna Machine Co. All rights reserved.

Web site designed and maintained by Design-2-Part Web Design.